Hot Products

Aramid microfiber powder

The products are made from a range of asbestos-free fibers to form yarn and cloth of various specifications., which become the skeleton material of friction sealing materials and meet the requirements of environmental protection.

Key words:Yarn for clutch dough sheet | Yarn for brake belt | Short fiber

hiddenValue

- Description

-

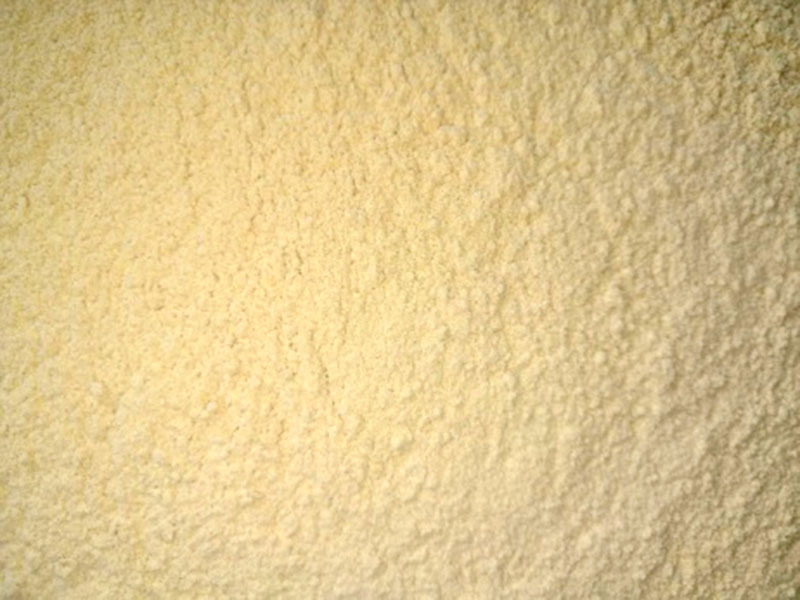

Aramid microfiber is light yellow powder processed from para-aramid fiber, and its micro-morphology is irregular fiber.

Para-aramid microfibers have excellent friction and wear properties, good chemical corrosion resistance, and good high temperature resistance as aramid fibers, and can be used for a long time below 400℃. The products are widely used to reinforce composite materials.

产品图片

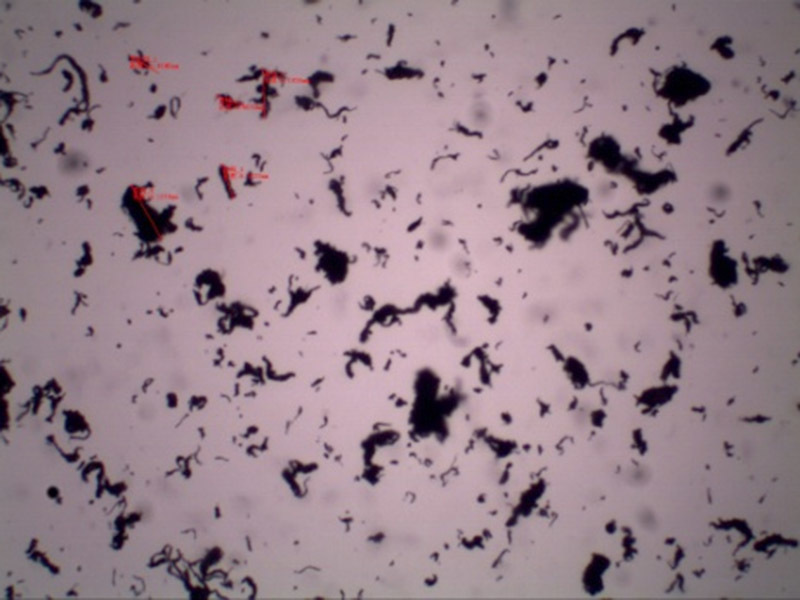

40X micrograph

Aramid microfiber is a kind of powder macroscopically. After the product is enlarged, the shape of single particle is irregular fiber, which has obvious enhancement effect on the product.

Main performance indicators of products:

Item

Data

Moisture content

≤5%

Stacking density

0.46g/ml

Microscopic morphology

Irregular fiber

Appearance color

Light yellow

Special fibers have different special properties, such as strong corrosion resistance, low wear, high temperature resistance, radiation resistance, flame resistance, high voltage resistance, high strength and high modulus, high elasticity, reverse osmosis, filtration, adsorption, ion exchange, light conduction, conductivity, and various medical functions.

Most specialty fibers are made by wet spinning. Some special fiber preparation processes are more difficult, such as spinning linear or low molecular weight fibers using traditional spinning techniques, and then undergoing cyclization, cross-linking, metal chelation, high-temperature heat treatment, surface physicochemical treatment or plasma treatment to produce finished fibers; In addition, new spinning processes such as lotion spinning, reactive spinning, liquid crystal spinning, dry jet wet spinning, phase separation spinning, high voltage electrostatic spinning, high-speed airflow melting jet and special composite spinning technologies are needed; Some also utilize existing synthetic fibers to obtain various ion exchange groups through functional group reactions or convert them into special fibers.

Messages

Our professional person will contact you asap!

Related Product

Contact Us

Nantong Xinyuan Special Fiber Co., Ltd.

Add:Longzheng Industrial Park, High-tech Zone, Hai'an City, Jiangsu Province

Tel:(86+513)88729008 88729009-8000

Fax:(86+513)88722868

Web:www.xyfibre.com

E-mail:xinyuan0513@126.com

Our Products

Leave us a Message

Copyright © 2023 Nantong Xinyuan Special Fiber Co., Ltd.